Facing the challenges of global climate change and the government's promotion of net-zero carbon emission policies, we have continued to make efforts to reduce greenhouse gas emissions for sustainable development. Through industryacademia collaboration, we incorporate AI big data technology into our process to improve efficiency and build smart factories.

We have actively implemented various management systems (ISO 50001, ISO 14064-1, ISO 14067, ISO 46001, ISO 14046, PSM, GRS), and referred to international technological development to propose various improvement plans, such as renewable energy, waste water, rainwater and sewer water recycling, energy conservation and carbon reduction solutions, smart energy management systems, etc., and followed the carbon reduction targets set by the Group to appropriately set annual carbon reduction targets and review renovation plans.

The verification certificates or product-related certificates obtained by the Company in 2022 (please see the link to the official website's Environment/Product Certification section).

+Energy conservation and Emissions Reduction Policy

- To meet the government requirements of Energy Conservation and Emission Reduction;

- Commitment to the company to Energy Conservation and Emission Reduction;

- Promote sector Energy Conservation and Emission Reduction strategy program;

- Implement the details of individual Energy Conservation and Emission Reduction.

We promise:

- Actively promote and develop Energy Conservation and Emission Reduction projects.

- Energy Conservation and Emission Reduction cases into the proposal to improve the system and to reward.

- At any time to carry out Energy Conservation and Emission Reduction propaganda work.

- Staff education and training, the implementation of Energy Conservation and Emission Reduction.

+Energy Conservation and Emission Reduction implementation report:

In response to the Glasgow Climate Pact signed by the 26th session of the Conference of the Parties (COP 26) to the UNFCCC and our government announcing the revision of the Greenhouse Gas Reduction and Management Act to the Climate Change Legislation, USI Group has re-evaluated its own carbon emission structure and carried out carbon reduction target planning. The carbon reduction target in 2030 is to reduce carbon emissions by 27% compared with 2017, and the Group has actively promoted the corresponding response strategies and management measures, and required the domestic production factories to plan and implement relevant action plans to be incorporated into the Group's renewable energy planning.

As of 2022, nearly 5.9 MW solar power has been developed. CGPC has followed the Group's carbon reduction goals and is expected to complete the 2030 emission reduction plan by the end of 2022 and re-adjust its own target for emissions reduction.

For the purpose of adaptation to the impact of climate change, CGPC has applied the Task Force on Climate-related Financial Disclosures from the Financial Stability Board in 2019 to identify risks and opportunities, as well as potential financial impact, and the identified results were used to set response plans.

Promotion of renewable energy

- CGPC starts it from the construction of solar photovoltaic equipment on the factory roof, and gradually expanded the use of green electricity in each factory area.

In 2019, CGPC's Toufen factory built roof-mounted 1,438 kWp solar energy equipment on its factory roof, and the actual power generation in 2022 reached 1.23 million kWh.

- CGPC will continue to expand the capacity of solar energy equipment, and is expected to add about 680 kWp of solar energy in the factory by 2023.

- TVCM’s Linyuan factory does not have a suitable roof space to put solar energy equipment. It plans to purchase 1.64 million kWh of green electricity and certificates by the end of 2025.

+The Group's cross-factory technical exchange seminar in 2022

In 2022, the technical exchange seminar in the Group's factory area was postponed to October due to the pandemic. It was in the format of case proposal competition, with "Occupational safety and environment protection", "Equipment preventive maintenance" and "Energy conservation and carbon reduction" being the core topics. After the reporting of technology examples and document review, a total of 7 proposals were submitted for voting. The executives and factories voted for the top three excellent examples, and the chairman of the Group presented certificate of excellence and reward money.

The selection and reward served as a good learning process to improve the Group's technology standard. USI Group has held the annual factories technical exchange seminars and several northern Taiwan and Kaohsiung factories resources consolidation meetings to share technical knowledge and discuss problems to achieve resources sharing and improve the effect of energy conservation and carbon reduction.

Implementation and results

- CGPC starts it from the construction of solar photovoltaic equipment on the factory roof, and gradually expanded the use of green electricity in each factory area.

In 2019, CGPC's Toufen factory built roof-mounted 1,438 kWp solar energy equipment on its factory roof, and the actual power generation in 2021 reached 1.23 million kWh.

- CGPC will continue to expand the capacity of solar energy equipment, and is expected to add about 680 kWp of solar energy in the factory by 2023.

- TVCM’s Linyuan factory does not have a suitable roof space to put solar energy equipment. It plans to purchase 1.64 million kWh of green electricity and certificates by the end of 2025.

▶

Information on Award-Winning Technical Case Studies in 2022:

➜

➜

➜

CGPCP's Linyuan

factory

(Excellent)

PVC Stripping

Improvements and

Optimization

▶

TVCM’s Linyuan factory has been awarded the first place in the Technical Case Study Presentation for two consecutive years!

Energy management

In compliance with the government's net-zero carbon emission goals,

energy-saving measures are being implemented: Voluntary reductions and

the implementation of various energy-saving initiatives within the facilities,

surpassing regulatory requirements.

●2022 Energy Conservation Performance (Target:1%)

| By company |

CGPC

(Toufen factory) |

TVCM

(Linyuan factory)

|

CGPCP

(Linyuan factory)

|

Power

conservation

(Target: 1%)

|

0.87% |

1.74% |

3.03% |

Description:

1.The data comes from the Bureau of Energy's annual energy conservation inspection system reporting form

2.

Description of achievement rate: In 2022, CGPC had fewer completed projects due to operating considerations

and equipment improvements. However, the company plans to continue the process of replacing outdated

equipment. TVCM and CGPCP's two plants have achieved their energy-saving targets.

Potential financial impact of risks and opportunities

| Type |

Climate-related risks |

Potential financial

impact |

Response measures |

| Physical |

Change in rainfall

(water) patterns and

extreme change in

climate patterns

|

- Increasing operating costs

- Increasing capital expenditure

- Decreasing asset value

- Decreasing revenue

|

Reconstruction of old rainwater ditch in Toufen factory: Added 2 external discharge outlets and sludge removal. The Phase of water ditch reconstruction plan is in

progress.

|

| Increased severity of

extreme weather events

such as typhoons and

floods

|

- Increasing operating costs

- Increasing capital expenditure

- Decreasing revenue

|

| Transition |

Rising raw material costs |

- Increasing operating costs

- Decreasing revenue

|

- Establish safety stock and review it regularly.

- Ensure a stable supply of raw materials.

- Grasp market changes as part of the purchasing strategy.

- Flexibly coordinate production and sales.

|

| Stigma of the industry |

- Increasing operating costs

- Increasing capital

- expenditure

- Decreasing revenue

|

- Strategic planning based on green research and development thinking (non-toxic) to develop non-PVC materials, for TPE, TPU, TPO and other green products.

- Replace VCM tanker truck unloading materials equipment to reduce VOC emissions. (Expected to be completed in Q4 2023)

- Carry out regular inspections, propose improvement countermeasures and add pollution prevention equipment: For process, refine and optimize the opening procedures

of the reaction tank to reduce VOC emission. (In progress)

|

| Raise the GHGemissions pricing |

- Increasing operating costs

- Decreasing revenue

|

- Monitor GHG emissions through annual inventory inspections.

-

Continue to pay attention to the trends in the revision of national climate change-related laws and regulations, and actively participate in public hearings on new (revised)research and development.

|

| Type |

Climate-related

opportunity |

Potential financial

impact |

Response measures |

Resources

efficiency |

Reduce water usage

and waste |

- Decreasing operating costs

- Increasing asset value

- Increasing revenue

|

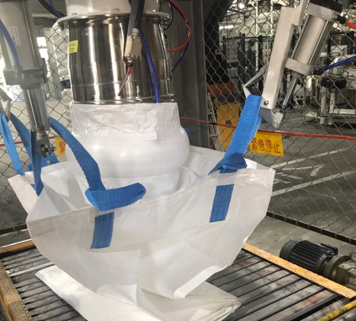

- Centrifuge dryer waste water recovery system (HBF) for recovered water, steam condensate, and coal boiler sedimentation tank uses effluent instead.

- Uses and benefits: The recycled water is reused in the cooling water tower, so as to reduce the dependency on using tap water and the discharge of waste water.

- The total volume of recovered water in CGPC and CGPCP is 775.7 million liters per year.

|

Use more efficient

production and

distribution processes |

- Decreasing operating costs

- Increasing asset value

|

- Equipment automation and energy conservation improvement

- Replacement of old equipment with new ones

- Use energy-conserving lights

- Promote smart manufacturing management system

- Set up automatic warehouses and improve transportation routes

|

Energy

source |

Use low-carbon

energy |

-

Decreasing operating costs

|

- Three plants have all passed the ISO-50001 energy management system verification.

- CGPC's Toufen factory has built a solar photovoltaic power generation system and designated a project team to evaluate the construction of renewable energy power generation equipment and purchase of green electricity.

|

Participate in carbon

trading market |

-

Decreasing operating costs

|

Product

service |

R&D and innovation

in developing new

products and

services |

- Decreasing operating costs

- Increasing revenue

|

- Smart machine testing and control equipment, optimize the PVC powder drying machine process to improve product quality and ensure energy conservation.

- Collaborate with customers to develop recycling of TPU shoe products and remanufacture them into shoe leather.

- Research and develop new varieties of non-toxic plasticizers and stabilizers to make PVC products.

|

| Resilience |

Participate in

renewable energy

programs and adopt

energy conservation

measures |

- Decreasing operating costs

- Increasing asset value

|

- Taiwan Power Company (Taipower) adjusted electricity prices on July 1, 2022, and April 1, 2023, as well as extended the summer electricity billing period. It isestimated that the annual electricity cost for 2023 will increase by approximately 30.4% compared to the electricity price adjustment made on July 1, 2022.

- Rented out the roof of CGPC’s Toufen factory. Vendors installed a parallel solar photovoltaic power generation system with approximately 1,438 kWp. CGPCrepurchased in May 2022. The 2022 wholesale to Taiwan Power Company amounted to 1,226,232 kWh.

- As of the end of 2023, install a solar photovoltaic power generation system with a capacity of approximately 680 kWp. It is projected that the installed solar capacity will reach around 2,118 kWp by 2025, with the remaining capacity to be planned and managed centrally by the group.

- In 2022, the three factories saved a total of 106,117 GJ in energy and reduced 6,461 tons of CO2e, about the carbon absorption volume of 17 Daan Forest Parks.

|

Energy alternatives/

diversification |

- Decreasing operating costs

- Increasing asset value

|